A Progressive Approach to Chillers

Experts in Refrigeration and Chilled Water Systems

Condominium

Commercial

Industrial

Institutional

The Approach

Industry Renowned Mechanics

Experts in Refrigeration and Chillers

In-House Energy Management

Predictive Analysis

Preventative Maintenance

Services

-

Chiller Maintenance

-

24/7 Service

-

Overhauls and Compressor Inspections

-

Chiller Retrofits

-

Chiller Control Retrofits

-

Energy Management

-

Asset Management Plans

-

Life-Cycle Cost Analysis

-

Predictive & Preventative Maintenance Plans

-

Building and Chiller Plant Optimization

-

Eddy Current Tube Testing

Your COMPLETE Solution.

Chillers are the most expensive part of any building’s mechanical system.

We understand that these machines present a large investment for property managers and owners and thus support our clients in enhancing performance and extending product life expectancy.

While some products cannot be saved due to inadequate maintenance by previous service providers, we can provide cost-effective, energy management solutions that meet client confidence.

We offer unmatched services for everything chiller.

Chiller Maintenance on all Chiller Makes

Chiller Emergency Service Calls

Retrofits

Chiller Overhauls and Compressor Inspections

Cooling Tower Services

Energy Management

With the industry’s most knowledgeable and skilled experts, we sweat the small stuff so that you don’t have to.

Our Mechanics

-

Industry renowned

-

Distinguished teachers at the Ontario College of Trades and Local 787

-

Manufacturer trained and certified

-

Trendsetters in approaches to chiller maintenance

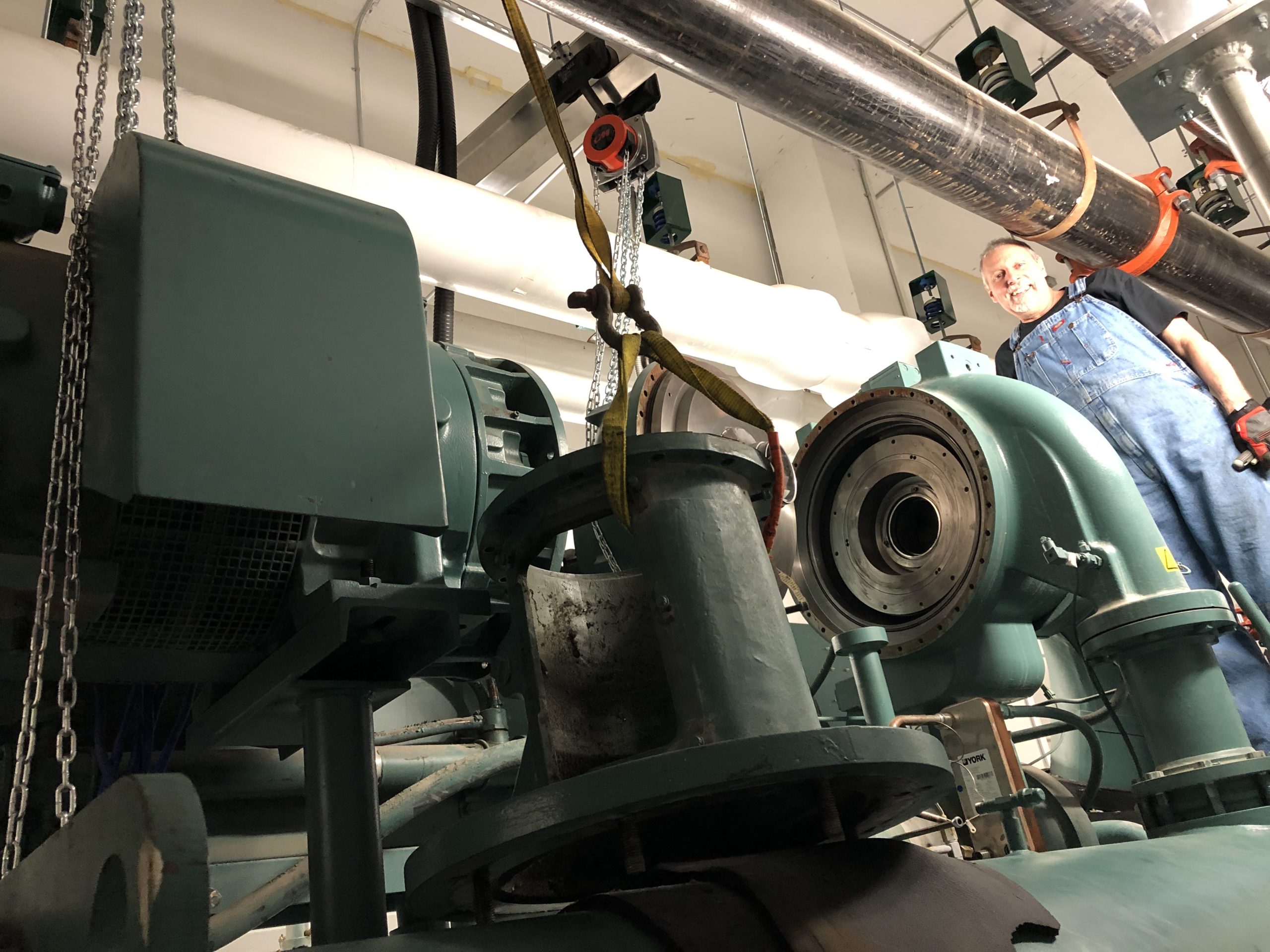

Overhauls and Compressor Inspections

How do we ensure the best service?

Comprehensive solutions provided by expert staff.

If regular maintenance of the chiller is ignored, it will cause unnecessary breakdowns and shorten service life. Without proper maintenance, deterioration of function and performance is inevitable.

Recommended every 10 years or 50,000 hours of operation, it is vital to understand the internals of the heart of your cooling system, the compressor. This service allows you to perform an educated evaluation of your system’s condition.

- Ensure Optimum Operation

- Gain Peace of Mind

- Prolong Equipment Life

- Avoid Unexpected Failures

- Reduce Maintenance Costs

- Discover Hidden Problems

- Life expectancy post-overhaul is approximately 10 to 15 years

CCS understands the importance of saving energy and maintenance costs. Chillers are expensive pieces of equipment that represent a large electricity load for most customers. To avoid unnecessary repairs, failures, and replacements, it is important to schedule thorough inspections and overhauls. (Chiller overhauls are important in prolonging the life and efficiency of the equipment. For the purpose of preventive maintenance, periodical overhaul maintenance is indispensable).

Every 25,000 hours or 10 years.

Our experts are trained in:

York Chillers

Daikin Chillers

Trane Chillers

Carrier Chillers

Smardt Chillers

Arctic Cool Chillers

Tandem Chillers

Multistack Chillers

Cooling Towers (B.A.C, Evapco,)

Energy Management

Shane Cote

Complete Chiller Solutions (CCS) is proud to announce Shane Cote as Service Foreman. Shane has over 20 years’ experience, specializing in York/JCI.

Reminding all Condominium Managers that it’s important to investigate your building’s cooling system ahead of time. CCS is busy prepping for the hot summer months. We want your residents to be comfortable. We hear it’s gonna be a HOT one. Let’s work together to ensure everyone is keeping cool.